Introduction

Aluminum twine bonding has emerged as a extreme approach inside the realm of electronics production, pretty within the semiconductor industry. As expertise advances, the want for valuable, reliable techniques of connecting chips to substrates turns into ever extra paramount. This article delves into aluminum cord bonding, exploring its programs, purposes, benefits, challenges, and long run developments. By awareness these aspects, authorities can make informed decisions referring to their cord bonding approaches and equipment.

Aluminum Wire Bonding: Methods and Applications

What is Wire Bonding?

Wire bonding refers to a largely used interconnect methodology that creates electric connections among microelectronic units and their substrates. The method involves utilising thin wires—more commonly manufactured from gold, aluminum, or copper—to ascertain these connections. It plays a imperative function in semiconductor packaging and is main for making certain that digital instruments feature easily.

Understanding the Wire Bonding Process

The wire bonding process is usually damaged down into a number of key steps:

Preparation: This includes cleansing the bonding pads on both the chip and substrate to ensure that top-rated adhesion. Positioning: The bond device positions the cord above the special zone on the substrate or chip. Bond Formation: Depending on the strategy used (ball bonding or wedge bonding), warm, ultrasonic strength, or power is carried out to form a mighty bond. Loop Formation: If required, a loop is shaped with the bonding cord to house movement and thermal expansion. Trimming: Excess twine is trimmed to finalize the bond.Types of Wire Bonding Techniques

When it comes to wire bonding procedures, a few approaches stand out:

- Ball Bonding: Utilizes a small ball at the give up of the cord created via heating it; most fulfilling for quality-pitch programs. Wedge Bonding: Employs a wedge-shaped device to create bonds; desirable for thicker wires. Ribbon Bonding: Involves due to flat ribbon-like wires for prime-density programs.

Each components has its distinct merits based on challenge requirements.

Wire Bonding Equipment Overview

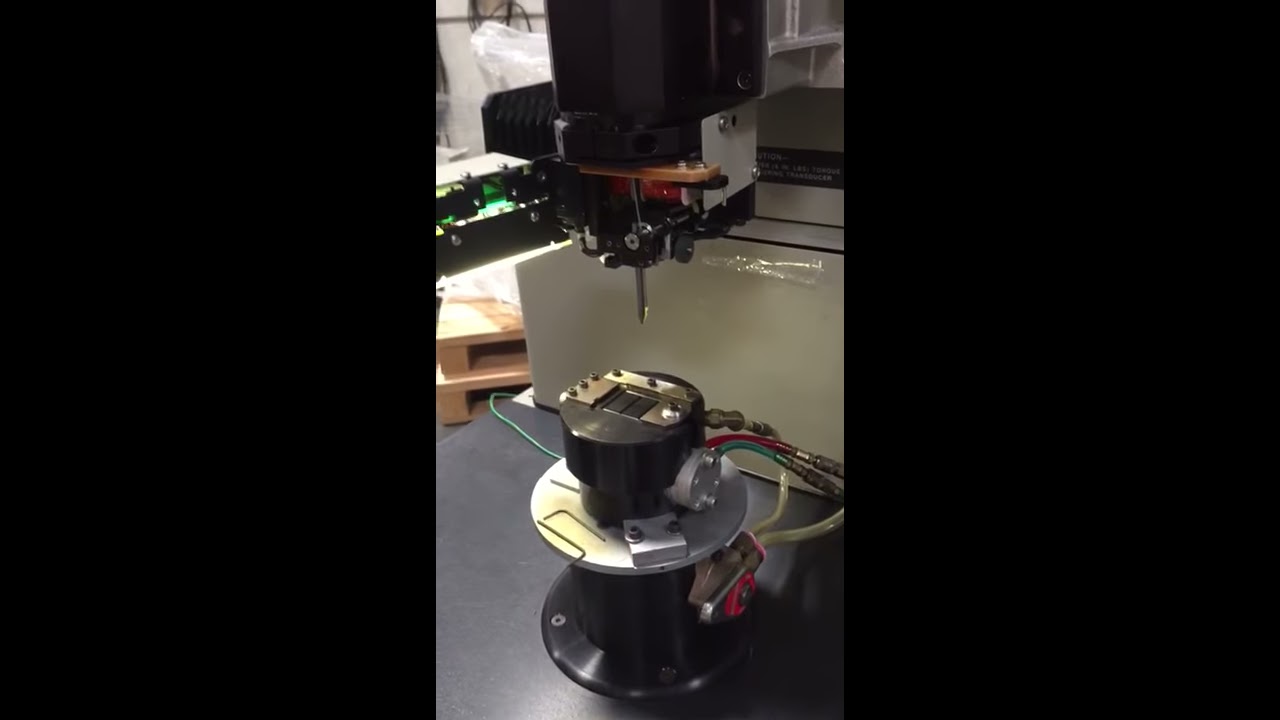

Wire Bonding Machines

Wire bonding machines are specialized package designed to automate the twine bonding activity. Key capabilities normally consist of programmable settings for distinct parameters reminiscent of temperature and strain.

Manual vs Automatic Wire Bonding Machines

While manual machines supply flexibility and manage over small batches, automatic machines offer efficiency for prime-amount construction. The preference extensively is dependent on production wishes.

Applications of Aluminum Wire Bonding in Electronics

Aluminum cord bonding unearths sizeable programs in a range of sectors:

- Semiconductors: Essential for connecting included circuits (ICs) on silicon wafers. Automotive Electronics: Used in sensors and keep watch over devices because of the its reliability lower than various stipulations. Medical Devices: Critical for making certain sturdiness in lifestyles-saving appliance.

These applications reveal aluminum's versatility in assembly today's digital demands.

Aluminum vs Gold Wire Bonding

When it comes to evaluating aluminum cord bonding with gold twine bonding:

| Feature | Aluminum Wire Bonding | Gold Wire Bonding | |--------------------------|-----------------------|--------------------| | Cost | Lower | Higher | | Oxidation Resistance | Moderate | Excellent | | Thermal Conductivity | Good | Excellent | | Usage | High amount | Specialty |

Aluminum provides rate-effectiveness whereas gold gives most beneficial overall performance in phrases of oxidation resistance.

Challenges in Aluminum Wire Bonding

Despite its advantages, aluminum wire bonding gives demanding situations:

Oxidation Issues: Aluminum can oxidize effortlessly; hence desirable cleaning is considered necessary earlier bonding. Bond Reliability: Variations in environmental stipulations can impression bond potential over the years. Quality Control: Ensuring steady best requires rigorous inspection protocols.Addressing those demanding situations is primary for retaining reliability microelectronics process in electronic additives.

Wire Bonding Failure Analysis

Failure prognosis in cord bonding contains analyzing faulty bonds to figure out their root motives—be it contamination or improper dealing with for the duration of creation.

Wire Bond Reliability Testing Methods

To make sure bond reliability, manufacturers appoint many different testing tools:

Pull Test: Measures bond energy by means of pulling on bonded wires till they holiday. Shear Test: Determines how smartly bonds resist shear forces via making use of lateral tension. X-ray Inspection: Non-harmful testing strategy that well-knownshows structural integrity without detrimental constituents.These checks are indispensable for first-rate assurance.

Future Trends in Aluminum Wire Bonding Technology

As expertise evolves, so does aluminum twine bonding:

- Innovative Materials: Research into new alloys may additionally raise performance and reduce rates added. Automation Advances: Enhanced automation will streamline techniques whilst enhancing precision. Miniaturization: As devices get smaller, suggestions will proceed evolving in the direction of finer pitches and tighter tolerances.

This steady evolution guarantees that aluminum is still appropriate amidst altering technological landscapes.

Conclusion

In summary, aluminum wire bonding plays an crucial position in trendy electronics manufacturing due to its distinct tricks and broad-ranging packages. Understanding its strategies—from forms of techniques hired to challenges faced—permits engineers and producers alike to harness its full attainable accurately.

FAQs

1. What are the primary kinds of resources utilized in wire bonding?

The predominant fabrics used are gold, aluminum, copper, and silver by reason of their conductive properties and differing rates related to each fabric %%!%%b13e7619-0.33-416d-8bd7-0401a711c3f5%%!%%.

2. How does thermosonic ball bonding range from other processes?

Thermosonic ball bonding combines warmness with ultrasonic vigor right through bond formation; this contrasts with purely mechanical or thermal approaches observed in different concepts inclusive of wedge or ribbon bonding.

3. What motives have an impact on bond reliability?

Factors come with environmental prerequisites (like humidity), cloth residences (such as oxidation resistance), bond pad design (length/tolerance), and good tools calibration for the time of manufacturing runs.

4. Can I automate my current handbook wire-bond approaches?

Yes! Transitioning from guide strategies probably calls for investing in programmable automatic machines which will tremendously amplify throughput at the same time slicing blunders linked to human dealing with.

5. What inspections needs to be accomplished publish-twine bonding?

Common inspections embrace visible tests (for evident defects), pull/shear trying out (to evaluate bond capability), x-ray inspections (for interior points), along environmental checking out if worthwhile centered on program requisites.

6. How do I make a choice among gold vs aluminum for my application?

Consider explanations like charge constraints versus overall performance needs; if oxidation resistance isn’t severe but funds constraints exist—aluminum may suffice—while gold suits high-performance eventualities requiring finest reliability.

This finished discussion on "Aluminum Wire Bonding: Methods and Applications" serves as both a assist and reference level for these seeking to deepen their expertise of this quintessential expertise inside electronics manufacturing at present!