Introduction

In the area of electronics manufacturing, the cord bonding method plays a pivotal position in setting up authentic electrical connections between semiconductor chips and their substrates. As expertise advances, so does the complexity of wire bonding operations. This complexity necessitates rigorous nice keep watch over measures to be certain operational efficiency, product reliability, and patron satisfaction. This article delves into the intricacies of twine bonding expertise, exploring the a good number of ways, gadget, and applications at the same time emphasizing the significance of satisfactory manipulate.

What is Wire Bonding?

Wire bonding refers to a set of techniques used to create electric connections among semiconductor devices via thin wires. These connections are elementary for making certain that digital resources function as intended. The cord bonding technique encompasses quite a lot of ways such as ball bonding, wedge bonding, and ribbon bonding, every one with distinguished advantages tailored to designated purposes.

Types of Wire Bonding Techniques

Ball Bonding- Process: Involves creating a small ball at the quit of a twine the usage of warm and ultrasonic potential ahead of attaching it to a bond pad. Applications: Commonly used for gold wire bonding in microelectronics.

- Process: Utilizes a wedge-shaped tool that presses the wire in opposition t the substrate. Applications: Effective for aluminum and copper wires in top-frequency applications.

- Process: Employs flat ribbons instead of around wires to set up connections. Applications: Ideal for energy modules by reason of their higher floor sector.

- Combines warm and ultrasonic vigour to boost bond power.

- Uses ultrasonic vibrations with out extra warmness for distinct supplies.

- Enables bonding in rough-to-reach spaces inside intricate assemblies.

How Wire Bonding Works

The foremost precept behind wire bonding includes using strain and warmth (or ultrasonic strength) to hitch metals by metallurgical interconnections. It starts offevolved with selecting accurate bonding wires—commonly gold, aluminum, or copper—relying on their conductivity and mechanical properties.

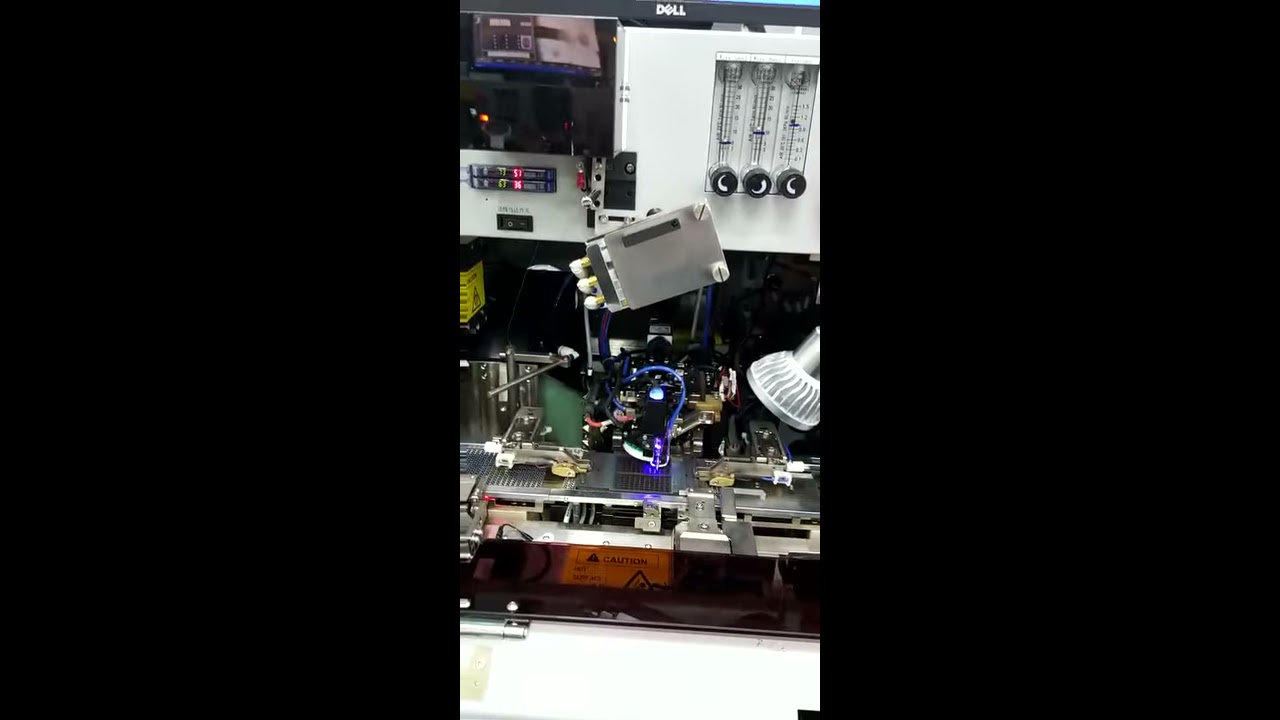

Wire Bonding Equipment Overview

Wire Bonding Machines

Modern wire bonding operations count number heavily on specialized machines tailor-made for assorted different types of bonds:

- Manual Wire Bonding Machine: Designed for low-quantity manufacturing; calls for human operation. Semi-Automatic Wire Bonder: Offers partial automation to improve productivity at the same time as nonetheless requiring operator enter. Fully Automatic Wire Bonder: Ideal for prime-volume creation; these machines can perform independently with minimum supervision.

Bonding Tools

Each equipment is outfitted with certain gear designed for most fulfilling performance:

- Bond Capillary Tool: Used to control and location the wire throughout bonding. Wedge Bonder Tool: Essential for achieving certain placements in wedge bonding tactics.

Implementing Quality Control Measures in Wire Bonding Operations

Quality keep an eye on performs a relevant function in making certain that wire bonds are legit and meet enterprise requirements. By enforcing systematic QC measures across the twine bonding course of, brands can noticeably reduce defects and boost product functionality.

Key Quality Control Techniques

Visual Inspection- Regular inspections may still be carried out to establish any noticeable defects akin to bond lifting or incomplete bonds.

- Techniques like X-ray inspection let brands to assess interior constructions with no detrimental areas.

- Measures bond force by utilizing a drive except failure occurs; supports examine bond integrity.

- Similar to tug checks yet makes a speciality of horizontal shear forces appearing at the bond interface.

- Maintaining controlled temperature and humidity tiers right through manufacturing can evade oxidation-related failures.

- Regular calibration of machines guarantees regular overall performance throughout alternative batches of products.

- Keeping thorough archives of every batch's parameters facilitates tracking again any defects or matters that arise post-construction.

- Continuous guidance packages for operators approximately highest practices in good quality warranty aid mitigate human mistakes all the way through operations.

- Establish partnerships with nontoxic suppliers who adhere to strict textile nice criteria reduces risks linked to inferior material.

FAQs

FAQ 1: What are straightforward themes encountered in twine bonding?

Common trouble comprise bond lifting, heel cracks, oxidation of bond pads, incomplete bonds, and illness for the duration of manufacturing approaches.

FAQ 2: How do you examine if a bond is robust sufficient?

Bond electricity might possibly be evaluated simply by pull tests or shear checks wherein managed forces are carried out until failure happens; outcome imply regardless of whether bonds meet required specifications.

FAQ 3: What material are broadly speaking used for twine bonds?

Gold, aluminum, copper, and silver are largely used materials caused by their top conductivity houses; determination most often relies on software requisites like thermal administration or payment concerns.

FAQ four: Why is environmental regulate principal in wire bonding?

Proper environmental controls help mitigate disadvantages related to moisture absorption and oxidation that can compromise bond integrity through the years; this can be fairly needed whilst operating with touchy factors like MEMS or RF modules.

FAQ five: Can I practice handbook inspections with ease?

Yes! However, relying solely on visual inspection can even introduce variability because of the human blunders; incorporating automatic inspection structures enhances accuracy seriously although imparting purpose exams over timeframes fundamental for bigger amount operations.

FAQ 6: What exercise components are readily available for researching about twine bonding?

Numerous on-line lessons exist covering everything from classic standards of the way cord bonding works by complex subjects like failure diagnosis; academic papers released by universities generally give insights into cutting-edge study traits inside this subject too!

Conclusion

Implementing Quality Control Measures in Wire Bonding Operations is not really simply an training yet an essential part that defines achievement in digital manufacturing nowadays. By targeting accomplished trying out methodologies mixed with powerful operational protocols—along ongoing lessons projects—enterprises can embellish their manufacturing talents even though minimizing danger motives associated with bad-high-quality connections made via unreliable approaches or applied sciences attainable to hand!

As we keep progressing towards more and more advanced digital designs pushing limitations forward—best warranty stays paramount! Thus making an investment time into knowing those procedures will yield dividends down line—now not simply financially yet also attractiveness-wise among peers inside of this dynamic industry area!