Introduction

In the fast-evolving world of electronics and semiconductor manufacturing, the wire bonding job stands as a quintessential approach for making risk-free electrical connections. From included circuits to drive modules, expertise and learning cord bonding innovations can critically beautify product functionality and reliability. This article delves into the intricate particulars of cord bonding science, exploring quite a number strategies, purposes, gear, disasters, and answers to ascertain most efficient outcome.

With a focal point on functional insights and technical depth, this finished information goals to provide engineers, manufacturers, and pupils with the competencies indispensable to excel in cord bonding. Whether you’re a pro specialist or a newcomer within the area, learning cord bonding approaches is major for accomplishing top quality electronic assemblies.

What is Wire Bonding?

Wire bonding refers to the system of connecting two metallic surfaces by way of a skinny twine that creates an electric bond. This formula is extensively used in semiconductor packaging and electronic software assembly to set up connections between chips and substrates or inside multi-chip modules.

The Importance of Wire Bonding in Electronics

Wire bonding plays a imperative function in guaranteeing electrical conductivity and mechanical steadiness inside digital units. Its importance extends throughout more than one industries:

- Semiconductors: Essential for chip-to-chip conversation. Automotive Electronics: Critical for protection structures like airbags. Medical Devices: Ensures reliability in existence-saving instruments.

How Wire Bonding Works

The twine bonding task comes to quite a few steps:

Preparation: The floor is cleaned to remove contaminants. Bonding: A warmth source (ultrasonic or thermosonic) softens the steel at the bond interface. Formation: The wire is pressed onto the surface driving a bonding device. Cooling: The bond solidifies because it cools down.Understanding how those stages interact enables engineers to optimize stipulations for more suitable bond quality.

Types of Wire Bonding Techniques

When discussing twine bonding techniques, it's central to comprehend that there are a number of procedures tailored for diversified packages:

Ball Bonding Process

Ball bonding entails growing a small ball at the conclusion of the cord before it makes contact with the substrate. This components is probably used by means of its efficiency and reliability.

Advantages:

- High capability bonds Suitable for advantageous pitch applications

Disadvantages:

- Requires definite control of parameters akin to warm and pressure

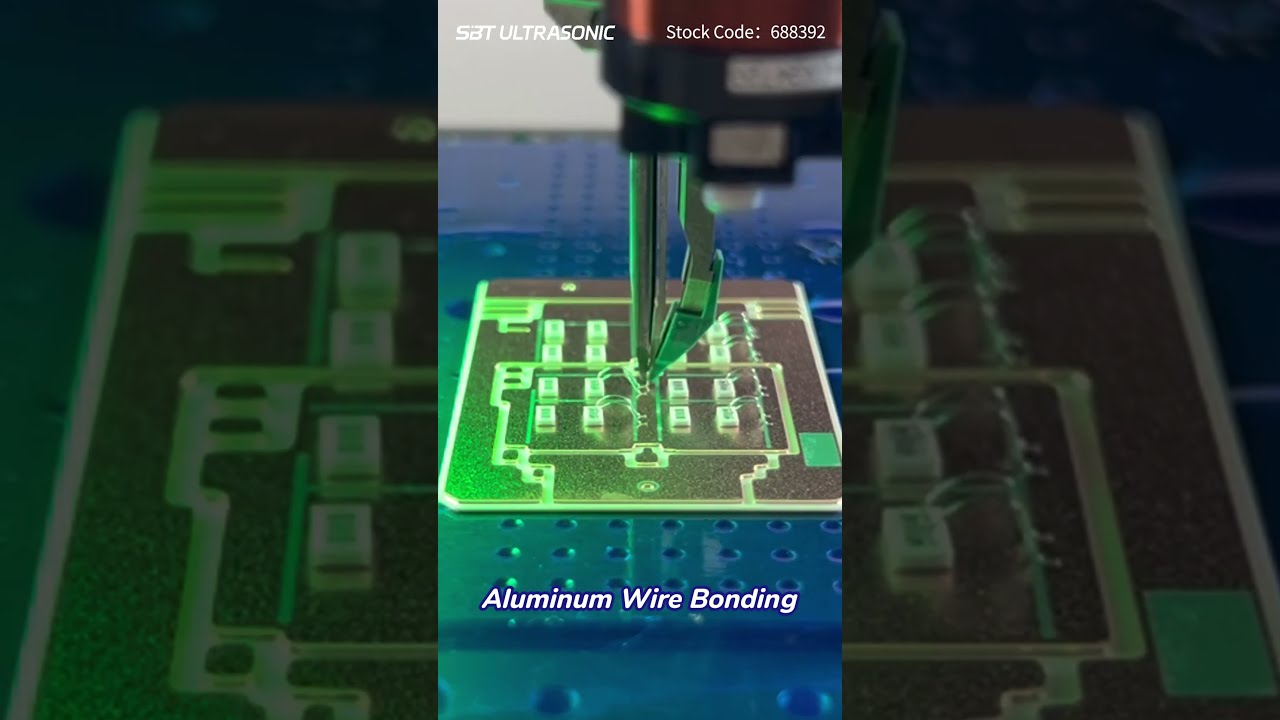

Wedge Bonding Process

Wedge bonding makes use of a wedge-shaped tool that presses immediately onto the material floor with no forming a ball. This system is most often Click for more most well liked when operating with aluminum wires.

Advantages:

- Lower expense when put next to gold Ideal for sizeable-region bonds

Disadvantages:

- May no longer achieve as powerful a bond as ball bonding

Ribbon Bonding Technique

This manner makes use of flat ribbons instead of round wires, taking into account increased floor arena contact which will bring about stronger thermal performance.

Applications:

- Power modules High-frequency devices

Wire Bonding Equipment Overview

To nicely execute any wire bonding strategy, different equipment and gear are required:

Wire Bonding Machine Types

Manual Wire Bonder- Operated manually; applicable for low-extent production.

- Combines handbook input with computerized controls; deals flexibility.

- Ideal for prime-amount manufacturing; maximizes potency and consistency.

Key Components of Wire Bonding Machines

| Component | Function | |--------------------------|-----------------------------------------------| | Ultrasonic Generator | Provides ultrasonic vigour for bonding | | Heated Capillary Tool | Applies warm all the way through bond formation | | Programmable Logic Control| Automates equipment operations |

Choosing the Right Wire Bonding Method

Selecting an acceptable twine bonding method is dependent on diverse points along with drapery properties, application necessities, and payment concerns.

Gold vs Aluminum Wire Bonding

When identifying among gold or aluminum cord bonding, engineers need to examine:

- Cost implications (aluminum is more commonly cheaper) Required electric qualities (gold can provide optimum conductivity)

Copper Wire Bonding Advantages

Copper has turn into more and more prominent because it adds striking electrical efficiency at cut down charges in contrast to gold or aluminum.

Factors Influencing Selection

Application type Environmental conditions Reliability requirementsWire Bonding Applications Across Industries

The versatility of wire bonding generation makes it possible for it to be utilized across quite a number sectors:

Wire Bonding in Semiconductors

Semiconductor units rely heavily on tough interconnections finished using triumphant cord bonding ways.

Key Uses:

- Chip packaging Multi-die configurations

Wire Bonding for Automotive Electronics

In car functions, where reliability is paramount because of the safeguard matters, stepped forward twine bonding tools are employed commonly.

Examples:

- Airbag systems Engine manipulate units

Wire Bonding Failure Analysis

Despite improvements in generation, mess ups can show up in the course of the twine bonding method:

Common Failure Modes

Bond Lifting: Occurs whilst inadequate drive or temperature results in vulnerable bonds. Heel Cracks: Result from stress throughout the time of thermal biking. Oxidation: Contaminants may perhaps compromise bond integrity over the years.Conducting Failure Analysis

To tackle those themes properly:

Use non-detrimental testing tricks like X-ray inspection. Perform pull checks and shear tests customarily to investigate bond strength.Mastering Wire Bond Quality Control

Ensuring quality bonds is primary in retaining product reliability:

Quality Control Techniques

Visual Inspection

Regular visual exams lend a hand catch defects early on.

Automated Inspection Systems

Implement robotic platforms capable with imaginative and prescient sensors for authentic-time tracking.

Understanding Wire Bond Reliability

Reliability tests are essential in predicting long-time period performance:

Factors Impacting Reliability

Environmental Stress (temperature fluctuations) Mechanical Strain (vibration publicity)By knowledge these factors, engineers can design greater resilient products through strategic drapery collection and processing circumstances.

Advanced Topics in Wire Bond Technology

As technologies evolves, so do methodologies surrounding wire bonding:

Low Temperature Wire Bonding

Emerging ingredients require adaptations in conventional strategies—low-temperature methods let triumphant connections with no adverse delicate factors.

Industry 4.0 Integration

Adopting intelligent manufacturing concepts enhances automation all over creation lines, increasing effectivity at the same time lowering human blunders right through wiring strategies.

Learning Resources on Wire Bond Techniques

For these eager about deepening their experience approximately wire bonding approaches:

Wire Bonding Tutorial – A comprehensive manual covering basics because of progressed practices. Webinars & Training Programs – Online programs hosted by means of business execs supplying insights into top-quality practices. Research Papers & Case Studies – Academic instruments exploring today's improvements within this field.Conclusion

Mastering cord bonding innovations calls for an understanding that spans typical principles due to complex programs throughout quite a lot of industries. By leveraging trendy technology along verified practices corresponding to good quality management measures and failure research routines—engineers can guarantee their products meet rigorous necessities at the same time as pushing forward innovation obstacles within electronics manufacturing ecosystems worldwide!

FAQs approximately Wire Bonding Techniques

What fabrics are in many instances used in cord bonding?

Most more often than not used fabrics incorporate gold, aluminum, copper, and silver owing to their perfect conductivity.

How does environmental manage have an effect on wire bonds?

Controlling humidity phases reduces oxidation hazards which make a contribution vastly in direction of getting better long-term reliability effects.

What factors have an impact on the decision among ball bonder vs wedge bonder?

Factors equivalent to utility model, rate constraints, and desired bond strength play pivotal roles right here.

li44/ol10/# What position does practise play in successful implementation?

Training guarantees technicians be aware of operational nuances most popular in opposition t fewer blunders which finally helps standard construction excellent advancements over the years.

6 . hr13hr13/##

In this widespread exploration into getting to know cord-bond innovations—regardless of whether you're crafting complicated microelectronics or potent automotive solutions—there's regularly extra room for increase!