Introduction

In the complex world of semiconductor manufacturing, twine bonding stands as a pivotal course of. This technique serves to set up electrical connections between the chip and its kit, making certain reliability and potency in electronic gadgets. Among diverse materials used for wire bonding, gold and copper are the maximum well-known contenders. Each subject material possesses exact attributes that make contributions to their functionality in alternative functions. In this text, we are going to delve into The Advantages of Gold vs Copper in Wire Bonding, exploring their qualities, reward, drawbacks, and suitability for a considerable number of kinds of twine bonding suggestions.

Understanding Wire Bonding Process

The cord bonding process contains connecting thin wires from a semiconductor die to its package deal or substrate by way of mechanical and thermal vigour. This methodology is mandatory for developing sturdy electric connections that resist operational stresses. The wires will also be created from countless elements, with gold and copper being the so much routinely used.

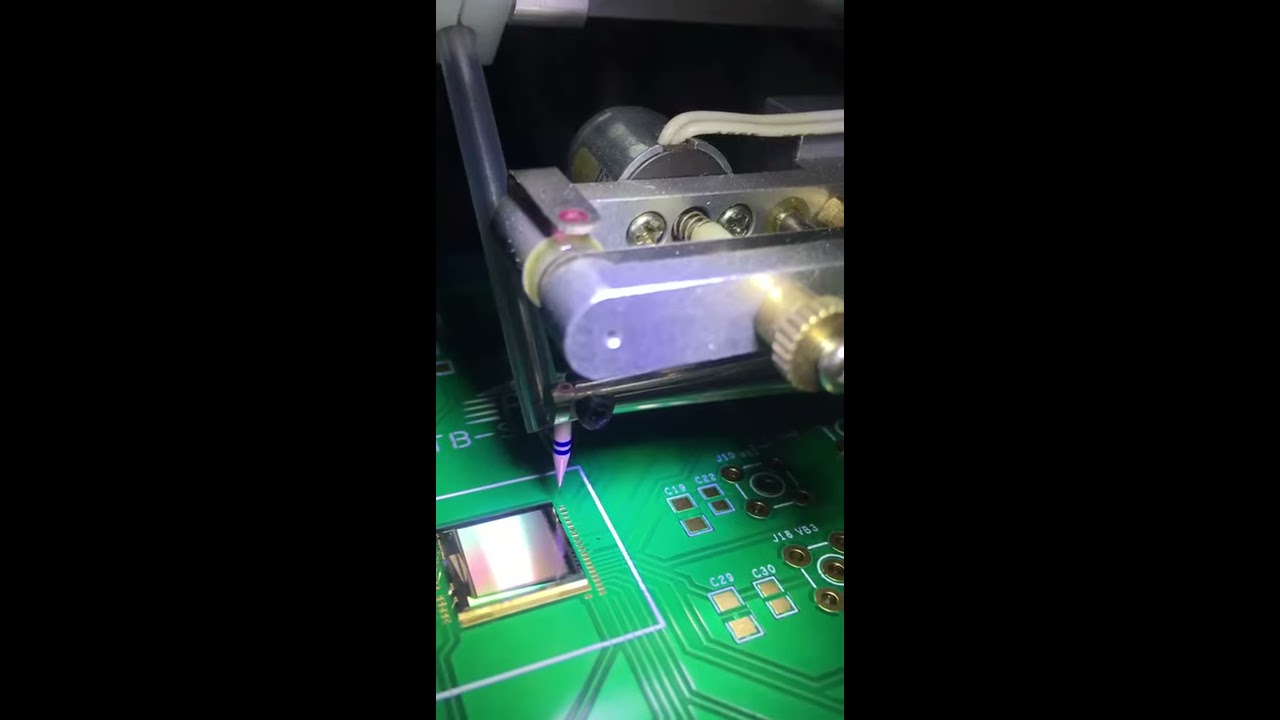

How Wire Bonding Works

Wire bonding in most cases employs both ball bonding or wedge bonding methods. In ball bonding, a ball is fashioned on the finish of the wire beforehand it is attached to the bond pad on the semiconductor die. Conversely, wedge bonding includes as a result of a wedge-formed software to create an ultrasonic bond among the wire and pad.

What Is Wire Bonding?

Wire bonding is a imperative interconnection technological know-how used primarily in semiconductors. It facilitates communique among chips and their packages even though maintaining low resistance connections critical for gadget performance.

Types of Wire Bonding Techniques

Ball Bonding Wedge Bonding Ribbon BondingEach process has its benefits centered on layout standards and cloth houses.

The Role of Materials in Wire Bonding

When determining substances for cord bonding, issues like can charge, reliability, conductivity, and thermal residences come into play. Let's discover how gold and copper degree up in opposition to every single different.

Gold Wire Bonding: Characteristics and Benefits

Gold cord bonding has been a simple within the trade because of a number of key benefits:

- Excellent Conductivity: Gold's excessive electric conductivity ensures minimum resistance. Corrosion Resistance: Gold does no longer oxidize quickly or corrode, which increases lengthy-time period reliability. Thermal Stability: Gold continues sturdy traits less than various temperatures.

Applications of Gold Wire Bonding

Gold cord is predominantly applied in excessive-reliability packages inclusive of aerospace electronics and clinical contraptions thanks to its robust overall performance.

Copper Wire Bonding: Characteristics and Benefits

Copper has gained reputation just lately as a result of its superb homes:

- Cost-Effectiveness: Copper is particularly more cost-effective than gold; consequently, it deals monetary blessings. High Electrical Conductivity: Although a bit much less than gold's, copper's conductivity is still really good. Strength: Copper bonds tend to be routinely stronger than the ones made with gold.

Applications of Copper Wire Bonding

Copper is largely used in buyer electronics in which rate-potency is paramount with no compromising too much on reliability.

Comparative Analysis: Gold vs Copper in Wire Bonding

Conductivity Comparison

Both gold and copper demonstrate satisfactory conductivity; in spite of this:

| Material | Electrical Conductivity (S/m) | Cost according to kg ($) | |----------|-------------------------------|------------------| | Gold | forty five x 10^6 | 60 | | Copper | fifty nine x 10^6 | 8 |

This desk illustrates why copper could be extra interesting from a charge perspective inspite of slightly shrink conductivity.

Reliability Factors

Reliability is needed when opting for materials for exact applications:

- Gold excels in environments more likely to corrosion. Copper’s susceptibility to oxidation requires protective measures yet grants gorgeous mechanical potential when desirable processed.

Wire Bonding Equipment Considerations

To gain preferable results in each styles of twine bonding techniques, specialized machine performs a imperative role:

Wire Bonding Machine Types

Manual Semi-Automatic Fully AutomaticEach style gives you various levels of manipulate over the bond good quality.

Wire Bond Inspection Techniques

Ensuring fine control for the duration of twine bonding comprises varied inspection innovations consisting of:

- Visual Inspection X-ray Analysis Pull Testing

These assessments help title advantage considerations early on.

Wire Bond Failure Analysis

Understanding customary failure modes related to either gold and copper wire bonds can assist mitigate hazards:

Common Failure Modes

Oxidation Mechanical Stress Thermal CyclingAnalyzing those elements enables engineers opt for very good elements elegant on program prerequisites.

Wire Bond Quality Control Measures

Implementing strict exceptional keep watch over measures at some stage in creation ensures long-time period reliability:

Techniques for Quality Assurance

Automated Inspection Systems In-line Testing Methods Detailed Documentation ProcessesThese measures are predominant for protecting top standards across all wire bonding functions.

FAQs About Gold vs Copper in Wire Bonding

1. What are the most important alterations among gold and copper wire bonding?

Gold provides best corrosion resistance at the same time as presenting tremendous conductivity yet comes at a top price factor when compared to copper that's greater cost-effective yet can oxidize if not right dealt with.

2. Which textile is more safe for automotive packages?

While both might possibly be used without problems in automobile electronics, gold's resistance to environmental factors makes it most suitable for excessive-reliability structures inside of this quarter.

three. How does the payment have an effect on alternative among gold and copper?

For top-amount manufacturing in which payment savings are important, producers commonly lean in opposition to copper; despite the fact, packages requiring durability may just justify applying gold regardless of top quotes.

4. What inspection methods are steered throughout the time of twine bonding?

Common strategies contain visual inspections blended with automatic X-ray testing to make sure that every one bond meets best standards easily formerly moving forward with construction techniques.

five. Can I use the two parts interchangeably?

Interchangeability isn’t a good option devoid of careful attention as both textile has dissimilar properties affecting bond electricity under varied conditions—consult great engineering rules in the past making substitutions!

6. Are there any inventions getting better those technologies?

Yes! Recent developments encompass improved processing innovations adapted mainly for copper that improve its efficiency features even though minimizing oxidation disadvantages all through production cycles!

Conclusion

In summary, awareness The Advantages of Gold vs Copper in Wire Bonding well-knownshows meaningful insights into cloth resolution based mostly on utility standards—each play obligatory roles inside of electronics production landscapes right this moment! While gold’s extraordinary reliability shines by means of targeted sectors like aerospace or clinical gadgets due largely due its corrosion-resistant nature; conversely low-settlement preferences corresponding to copper dominate shopper electronics markets pushed by using fiscal motives! Ultimately deciding upon correctly among them hinges upon balancing efficacy towards price range constraints—a job made more effective via grasped experience shared here!

This entire exploration not best highlights key differences but additionally palms execs with helpful documents pivotal closer to making educated decisions across diversified industrial contexts—eventually shaping long run trends within this Home page ever-evolving domain!